Your advantages in metal processing with our robot

- Precise: HORST has a repeatability of +/- 0.05 mm.

HORST guarantees you the highest quality

in metal processing. - Smart: HORST has all the interfaces commonly used in the industry.

IoT—open interfaces for transferring programs, actuating external machines, and incorporating safety-relevant components. - Flexible: HORST is compact and flexible.

HORST is compact and flexible. Thanks to its simple programming, it guarantees quick changeover times, allowing alternating production processes to be implemented in a quick, easy, and cost-efficient way. - Efficient: Produce safely and quickly with HORST.

HORST maximizes efficiency and increases the quality, consistency, and speed of production in metal processing.. - Simple: Your entry into automation.

HORST makes it easy to get started with robot-based automation. The horstFX software guarantees easy programming and ensures fast changeover times.

Already convinced?

Get to know HORST?

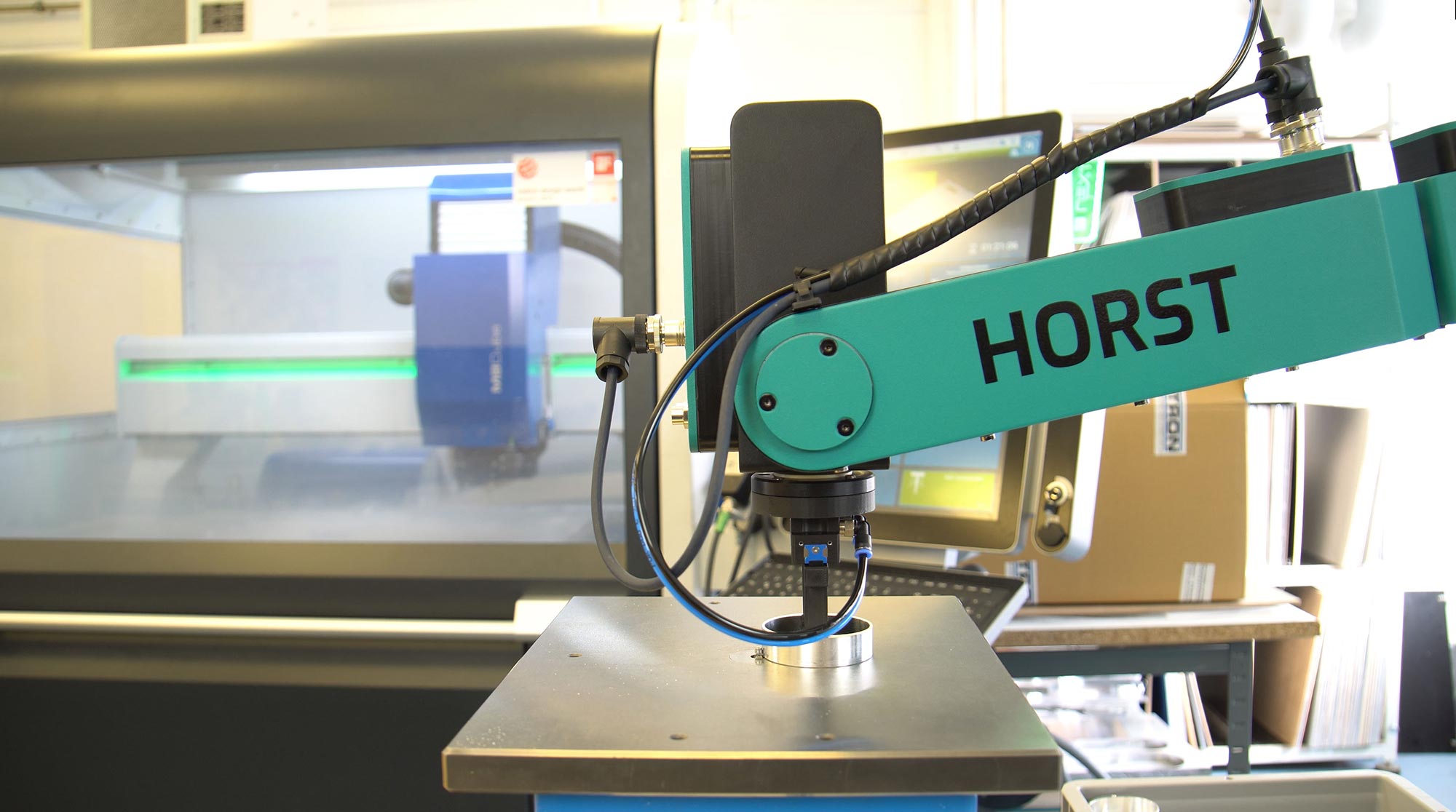

Industrial robot HORST - Your robot for metal processing

Whether it’s cutting or non-cutting manufacturing processes—as an industrial robot, HORST was developed for the metal processing sectors. It can communicate and interact with all common machine tools.

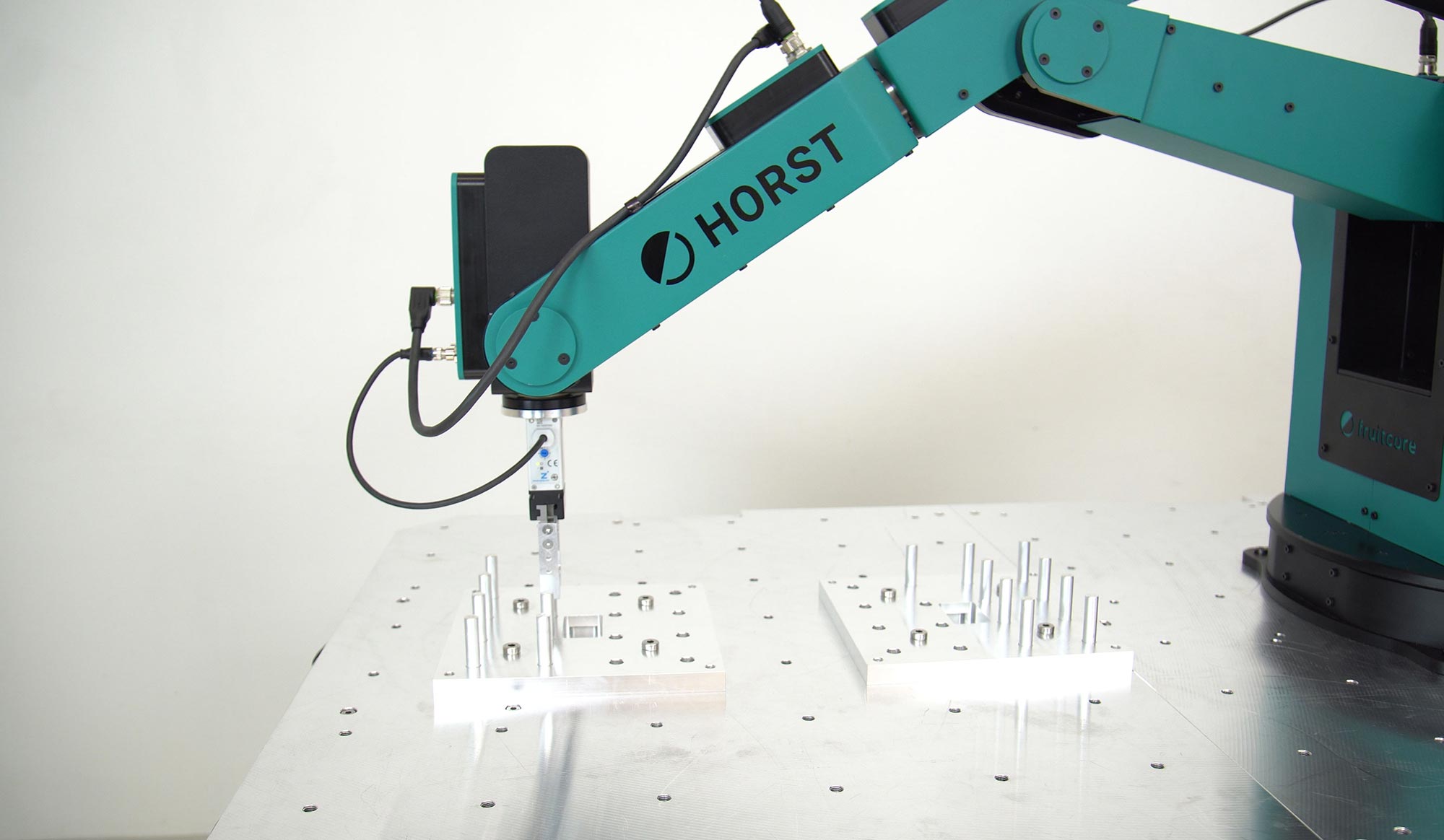

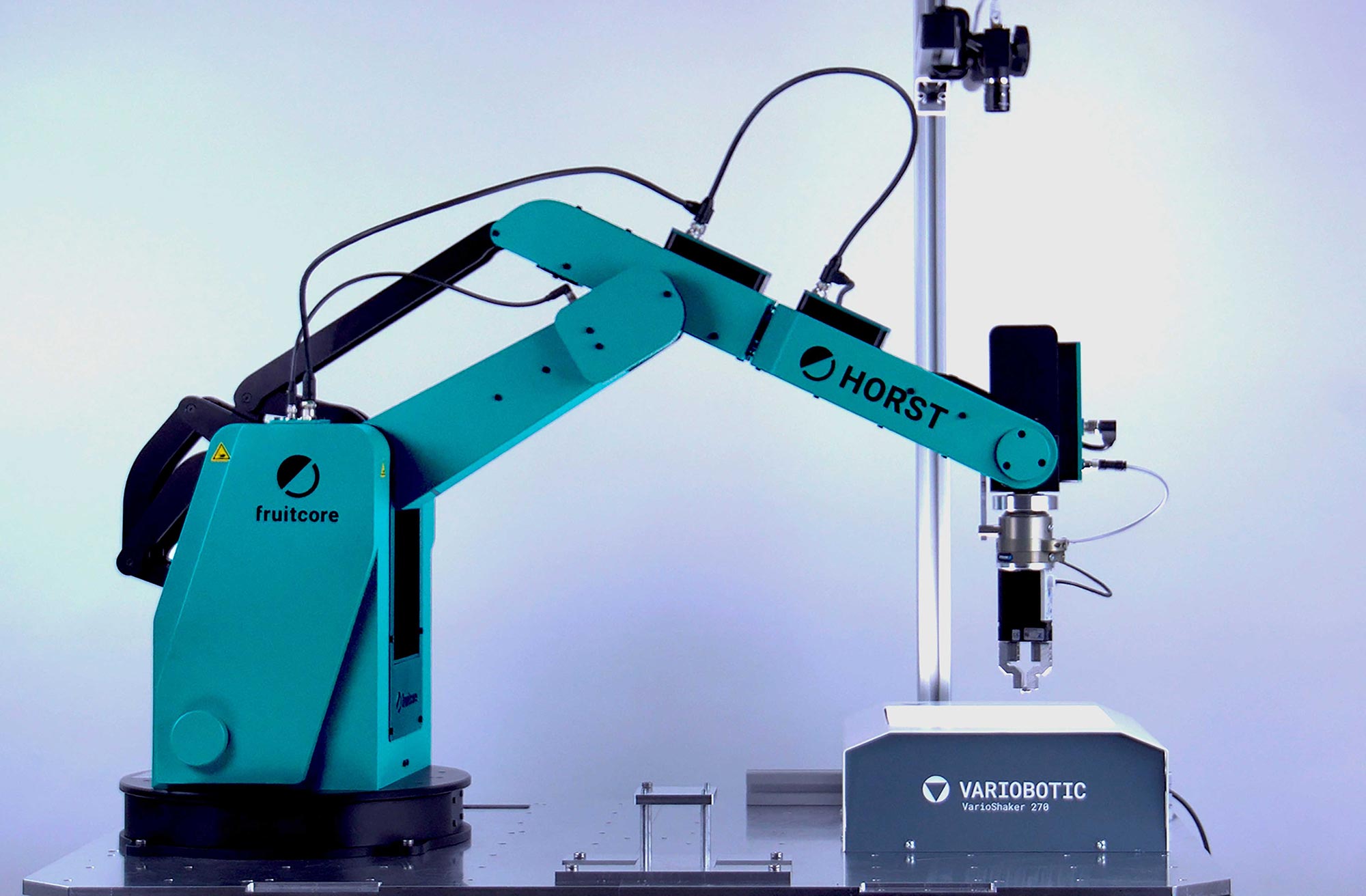

The 6-axis industrial robot HORST from fruitcore robotics is characterized by its straightforward connection to external machines. In cooperation with a wide range of grippers, suction cups, dispensers, or optical image processing systems, it can perform a variety of automation tasks with ease and efficiency.

Precision is imperative in metal processing and it can be increased considerably with a robot-based automation solution. With a repeat accuracy of +/- 0.05 mm, HORST is extremely precise and therefore ensures consistent quality. HORST performs all the tasks assigned to it with ease, even under occasionally difficult or extreme working conditions.

HORST is equipped with the horstFX software, which is easy to operate. It is designed to be intuitive and convenient and was developed specially for touchscreens, and the included operating panel horstPANEL in particular. For more advanced functions, you can also operate horstFX on your desktop, using a mouse and keyboard. This way, you can enjoy all the possibilities.

HORST is flexible and can be used for various processes. Thanks to quick and easy programming and the straightforward connection to external machines, the changeover times when converting production to new workpieces can be reduced to a minimum. This saves time and money!

Therefore, HORST is your robot for metal processing.

Experience report: How our robot copes with metal processing

SBS-Feintechnik GmbH & Co. KG from Schonach in the Black Forest is the parent company of the BURGER GROUP and specializes in customer-specific drive technology in the sectors of building technology, medical engineering, machinery and plant engineering, and household appliances, for example.

HORST was able to cover all the requirements for the requested highly flexible automation solution in the metal processing process. SBS-Feintechnik GmbH & Co. KG uses the industrial robot in the assembly of electric motors for the automotive area. Its ease of operation, flexible application, and high precision were just some of the reasons why the company decided in favor of HORST.

Your experts in robotics

Markus Mayr & Jan Meel

+49 (0)7531 94599 44

horst@fruitcore.de

Have we aroused your interest?

Get in touch! Together we will find out which version of our industrial robot is best suited for your application.

HORST in Action

Workpiece handling for machine tools: Automated loading and unloading of a DATRON milling machine with industrial robot HORST.

Our robot performs these metal processing tasks

Cutting processes

Whether it is sawing, filing, thread cutting, reaming, slotting, turning, milling, or drilling – HORST performs all tasks in cooperation with external tools with precision and reliability. Thanks to horstCONTROL, external machines can communicate easily via common interfaces.

Non-cutting processes

(Primary) forming, eroding, coating, hardening, annealing, or joining—our industrial robot can also be used in a variety of non-cutting processes. HORST ensures consistent levels of quality and maximizes efficiency.

Testing

HORST tests your parts reliably, easily, and with consistent quality. Contact-free testing, measuring, or simple OK/not OK tests are no problem for HORST.

Palletizing

HORST is a master at palletizing. No matter how large or small your part may be, HORST will safely carry your parts from A to B.

Sorting

HORST brings order into chaos. With the vision system or parts separator, HORST can sort your unsorted parts quickly and precisely.

Our robot system is available in the following versions

Industrial robot HORST600

Robot system including control, operation panel and horstFX.

Industrial robot HORST600 lab

Robot system including control, operation panel and horstFX.

Industrial robot HORST900

Robot system including control, operation panel and horstFX.

Industrial robot HORST1400

Robot system including control, operation panel and horstFX.

Frequently asked questions about robots in metal processing

Robots are now an inherent part of production processes in the metal industry and perform a variety of tasks. For example, they are used in non-cutting processes such as (primary) forming, eroding, coating, hardening, annealing, or joining, or in cutting processes such as sawing, filing, thread cutting, reaming, slotting, turning, milling, or drilling. HORST also performs all of these tasks in cooperation with external tools with reliability and precision, and is used by many customers in the metal processing sector.

Using an industrial robot in metal processing requires straightforward communication and interaction between the robot and all common external tools and systems. This is the only way that the robot can perform cutting and non-cutting production processes.

Another requirement that an industrial robot must meet in order to be used effectively in metal processing is precision. With a repeat accuracy of +/- 0.05 mm, HORST is extremely precise and therefore ensures consistent quality. The 6-axis industrial robot HORST from fruitcore robotics is characterized by its straightforward connection to external machines and can perform a variety of automation tasks with ease and efficiency.

An industrial robot must also be able to cope with sometimes difficult or extreme working conditions in the field of metal processing. HORST was developed as an industrial robot for metal processing and performs the tasks assigned to it effortlessly.

Industrial robots are also referred to as all-purpose robots because they are very flexible in terms of application. In combination with our mobile robot base in particular, our industrial robot HORST is very flexible and can be used for any kind of application. This is of great interest in metal processing in particular. Do you have different machines for which you are looking for an automation solution? In that case, HORST is ideally suited for your needs.

Thanks to its different ranges, HORST is an all-purpose robot.

And not only that, HORST’s intuitive software is also convincing. You can create complex sequences in just a few minutes with horstFX. No programming skills required!

With its simplicity of programming and unique cost–benefit ratio, HORST is your opportunity for a simple and affordable introduction to automation.

In order to work with a robot, you need other components aside from the robot itself. The costs of a complete robot system are therefore as individual as the requirements arising from the process to be automated.

In addition to the pure acquisition costs for the robot itself, costs will arise for the peripherals, i.e. special add-on parts such as grippers, suction cups, or other tools. Individual requirements arise depending on the area of application and range of tasks, and the robot must satisfy these with its equipment. Further expenses usually include system engineering, project management, commissioning, actual operation, servicing and maintenance.

Thanks to its innovative kinematics and the accompanying drive concept, 6-axis industrial robot HORST is designed for the unproblematic use of standard drives. This is why HORST offers a significant price advantage as compared to competing products despite the fact that we produce in Germany and therefore deliver top quality.

By the way, HORST is not only less expensive to purchase. The industrial robot is also very economical and low-wear in ongoing operation. Since it is so easy to program, you save time and therefore money as well!

Due to their universal range of applications, industrial robots are used efficiently in metal processing. In combination with external components, a robot is capable of performing a wide range of cutting or non-cutting production processes. As a 6-axis industrial robot, HORST was developed precisely for these sectors. Communication and interaction with a wide range of machine tools is possible thanks to the common industry interfaces on horstCONTROL. Robot-based automation solutions offer a high level of precision. With a repeat accuracy of +/- 0.05 mm, HORST is also extremely precise and therefore ensures consistent quality. In addition, HORST performs monotonous, dangerous, and strenuous tasks and reduces the risk of injury.