Your advantages in workpiece testing with our robot

- Precise: HORST impresses with its precision.

With a repeatability of +/- 0.05 mm, HORST ensures high and consistent quality. - Smart: HORST has all interfaces commonly used in the industry.

IoT - open interfaces for transferring programs, controlling external machines and integrating safety-relevant components. - Flexible: HORST is compact and flexible.

HORST can be used efficiently for numerous applications in the field of workpiece inspection. - Efficient: Produce safely and quickly with HORST.

HORST maximizes efficiency and increases quality, consistency and production speed in workpiece inspection. - Simple: Your entry into automation.

HORST makes it easy to get started with robot-based automation.

The software horstFX guarantees simple programming and thus creates fast changeover times.

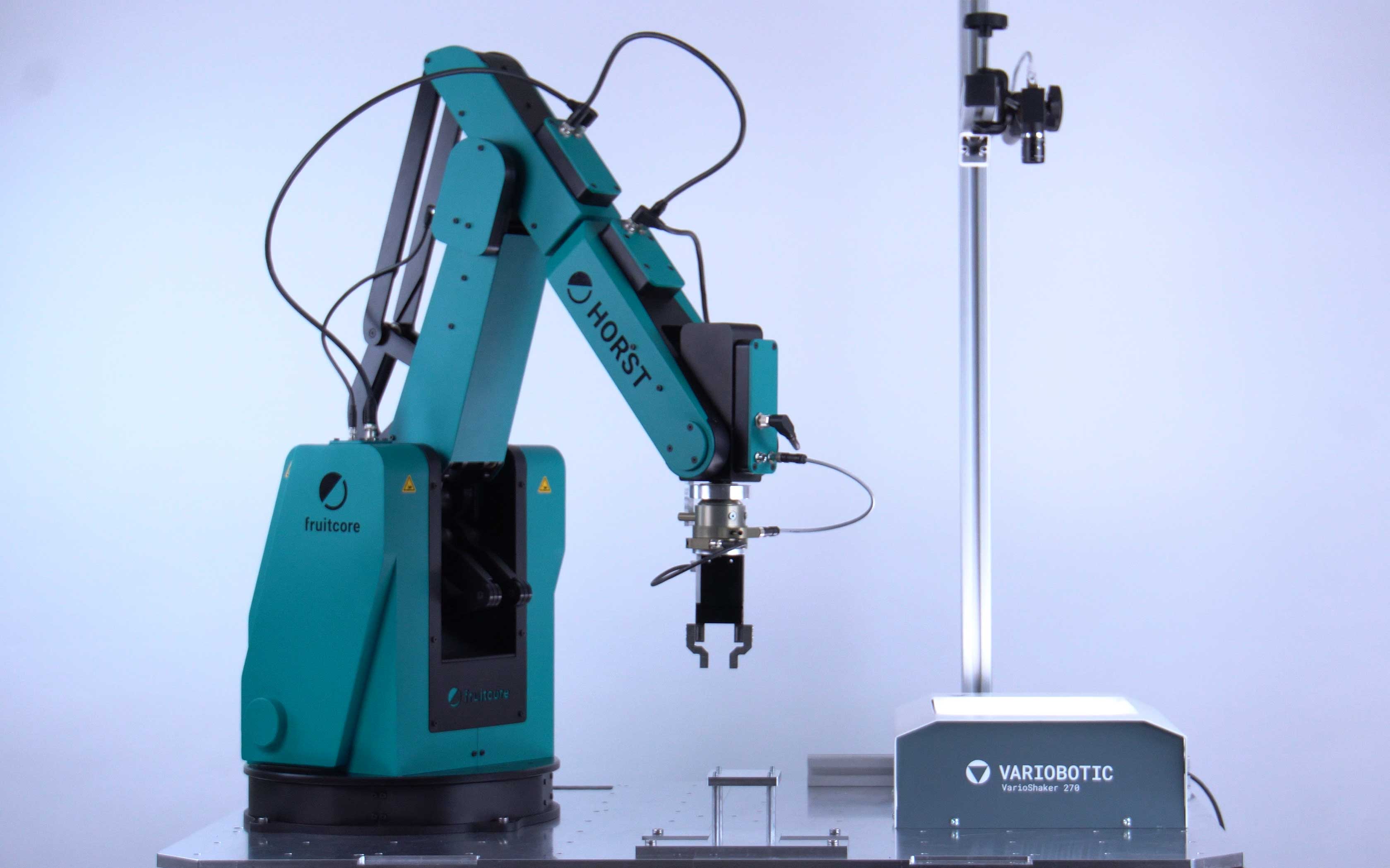

Industrial robot HORST - Your robot for workpiece testing

Measuring, gaging, or contact-free testing—HORST is just as familiar with complex processes as it is with simple OK/not OK tests. HORST’s ability to concentrate stands out in workpiece testing.

Even the smallest malfunctions can result in changes in the measured values. With a repeat accuracy of +/- 0.05 mm, 6-axis industrial robot HORST is extremely accurate and therefore also ensures consistent quality of workpiece testing.

With its uniform sequences of movement and the accompanying exact positioning of the workpieces, HORST ensures that inaccuracies and user errors can be ruled out. This allows the certainty of the test results to be increased reliably. In combination with effectors or external systems such as visual systems, HORST performs pass and fail tests, measures and checks surfaces, and sorts workpieces.

HORST is flexible and can be used for various applications. Thanks to quick and easy programming and the straightforward connection to external machines, the changeover times when converting production to new workpieces can be reduced to a minimum. This saves time and money! HORST is light, doesn’t take up much space, is easy to handle, and therefore suited for a wide range of tasks within the context of workpiece testing. For example, HORST can easily perform checks even of alternating small-scale series and is the ideal partner for your automation.

Convinced?

Get to know HORST first?

Experience report: How our robot copes with workpiece testing.

Automotive supplier Koepfer Zahnrad- und Getriebetechnik GmbH relies on HORST for workpiece testing and laser marking of gearwheels for all kinds of engine-related applications. On the combined system, the industrial robot from fruitcore robotics marks gearwheels and performs error checking on the components. Not only does this allow Koepfer work efficiently and take some of the burden off of its employees, but HORST also sorts out faulty gearwheels reliably and ensures process-reliability.

Your experts for robotics

Markus Mayr & Jan Meel

+49 (0)7531 94599 44

horst@fruitcore.de

Are you interested in our products?

Contact us! Together we will find out which version of our robot is best suited for your application.

Our robot performs these workpiece testing tasks

OK/not OK test

Whether you want to use HORST to test finished parts or perform inline measurements in your production process, 6-axis industrial robot HORST offers variable solutions for your automation. In combination with effectors or external components such as visual systems, HORST performs pass and fail tests, measures and checks surfaces, or sorts workpieces. HORST is ideally suited for automating testing and measuring tasks at low cost and ensuring the highest level of quality for your products.

Contact-free testing

In combination with industrial image processing technology, HORST can not only see but also grip and grasp. This way, HORST can use its camera system or optical sensors to perform contact-free testing of your parts. Thanks to its high repeat accuracy, precise sequences of movement, and fast execution, HORST is the perfect solution for ever more complicated testing and measuring applications.

Measuring. Gaging.

Measuring and gaging pose no problem for HORST either. HORST serves as the technological basis for the process-reliable implementation of various measuring programs.

The common industry interfaces allow the flexible and simple connection of complex sensor systems, for example 2D and 3D vision systems, force/torque sensors, as well as other external tools and machines.

Our robot system is available in the following versions

Industrial robot HORST600

Robot system including control, operating panel and horstFX.

Industrial robot HORST600 lab

Robot system including control, operating panel and horstFX.

Industrial robot HORST900

Robot system including control, operating panel and horstFX.

Industrial robot HORST1400

Robot system including control, operating panel and horstFX.

Frequently asked questions about robots in workpiece testing

The potential of robotics in the industrial environment is near inexhaustible. Industrial robots can perform a variety of tasks in workpiece testing as well. They constitute the technological basis for the process-reliable implementation of measuring programs. External components and complex sensor systems, for example force/torque sensors or 2D and 3D vision systems, can be connected via interfaces.

The smallest malfunctions in the production process can result in changes in the measured values. Thanks to the high repeat accuracy, precise sequences of movement, and fast execution, industrial robots are the perfect solution for ever more complicated testing and measuring applications. With a repeat accuracy of +/- 0.05 mm, HORST is extremely precise and guarantees consistent quality in workpiece testing.

Selecting the suitable robot is essential for planning your automation solution, considering that the expenses and the skills required for commissioning, programming, and setting up the workpiece testing to be automated vary strongly depending on the robot manufacturer. For example, different manufacturers use different programming languages and software. While it is rarely cost-efficient to train your own personnel, external solutions are often inflexible. This complexity often results in fixed programmed applications, inflexible sequences of movement, or rigid positions in the production process.

fruitcore robotics has focused its attention on the user-friendliness of HORST, and with the horstFX software, which was developed specially for HORST, the company has created a system that can be commissioned without any programming skills whatsoever—just plug-and-play.

horstFX was developed specially for use with the accompanying touchscreen and features an intuitive and convenient setup. Using a digital twin, the 6-axis robot can be moved on the display using a finger. Numerous applications follow the same patterns, which have already been programmed as preset features in the software. For more advanced functions, you can also operate horstFX on your desktop, using a mouse and keyboard. HORST offers you a great variety of possibilities and the industrial robot is flexible in terms of its application. The straightforward programming and easy connection with external machines make commissioning and setting up your HORST quick and effortless. This also reduces the changeover times to a minimum when switching over production. This saves time and money and retains flexibility.

The costs of a robot system are as varied as the automation solutions to be implemented. An operational robot system consists of not only the robot itself but also the components required for the automation, such as grippers, suction cups, and other external tools. Additional expenses such as those for system engineering, project management, commissioning, and actual operation, as well as servicing and maintenance must also be considered.

The robot system HORST consists of the 6-axis industrial robot HORST, horstCONTROL, the horstPANEL operating panel, and the horstFX software. The innovative kinematics offers an unbeatable cost–benefit ratio, as HORST can be equipped with standard drives and does not require any cost-intensive special solutions. Our robot is very economical and low-wear even in ongoing operation. Since it is so easy to program, you can save time and therefore costs as well.